The Journey of Industrial Minerals : From Mine to Market

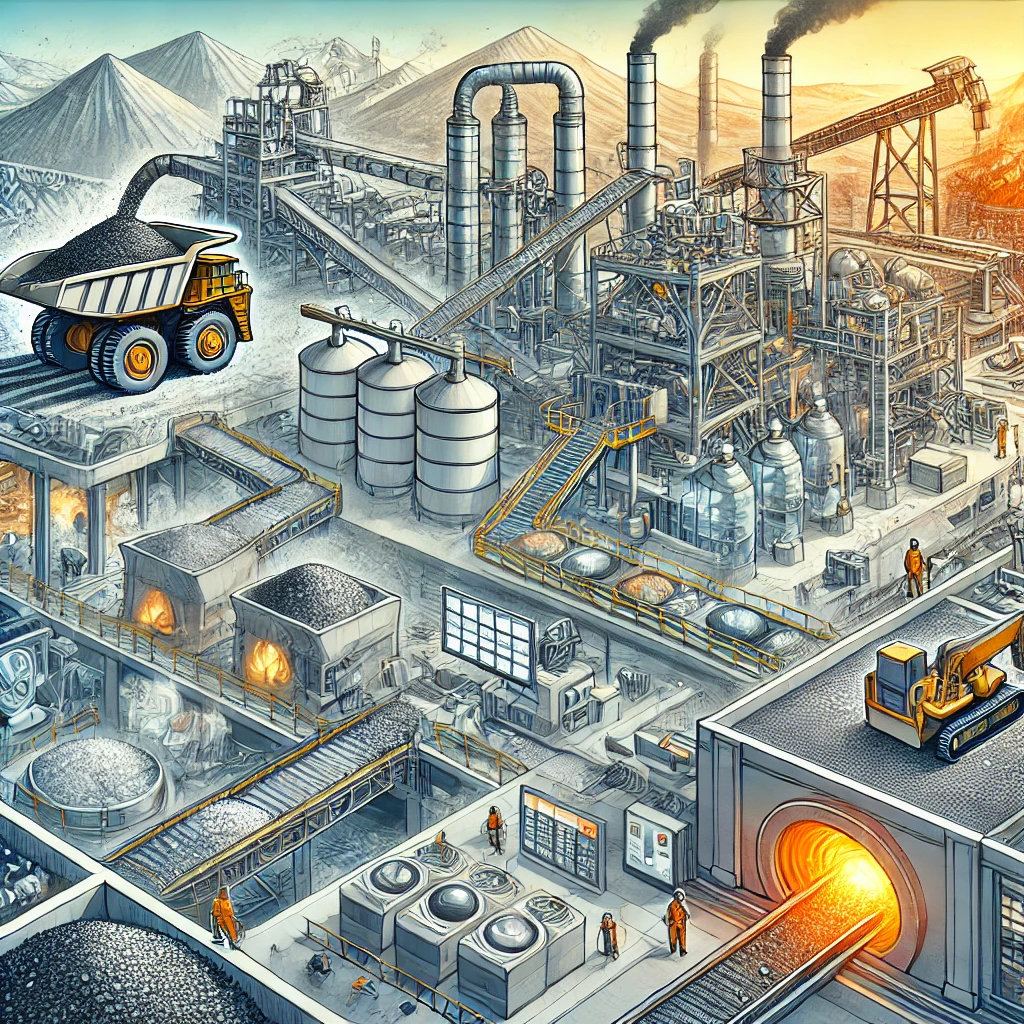

Industrial minerals play a pivotal role in shaping modern industries, serving as the backbone for countless products and applications. From the construction of towering skyscrapers to the batteries powering electric vehicles, these minerals undergo an incredible transformation journey — starting as raw materials and culminating in refined, finished products that meet the demands of global markets.

In this comprehensive blog, we delve into the fascinating journey of industrial minerals, exploring each stage of their transformation and the innovations driving this essential industry forward.

1. Sourcing the Raw Materials

The journey begins with sourcing industrial minerals from natural deposits such as mines, quarries, or sedimentary basins. Minerals like silica sand, bauxite, and limestone are extracted through environmentally responsible mining practices.

- Key Challenges: Sourcing involves overcoming geographical, geological, and environmental challenges. Ensuring sustainability in this stage is critical.

- Technological Advancements: GPS mapping, remote sensing, and drone technology are now widely used to identify mineral-rich deposits with minimal environmental disruption.

2. Initial Processing and Preparation

After extraction, the raw minerals undergo primary processing to remove impurities and prepare them for further refinement. Techniques such as washing, crushing, grinding, and screening are employed to ensure consistent quality and size.

- Example: Bauxite is crushed and washed to produce alumina for aluminum production, while silica sand is processed to meet the purity standards for glass manufacturing.

- Environmental Focus: Water recycling systems and dust suppression techniques are becoming integral to minimize environmental impact during processing.

3. Refinement and Transformation

Once processed, the raw minerals enter the refining stage, where they are transformed into forms suitable for specific industrial applications.

- Metal Powders: Minerals like zinc, copper, and nickel are refined into high-quality powders for use in batteries, coatings, and alloys.

- Cement Clinker: Limestone and other raw materials are heated in kilns to form clinker, the precursor to cement.

- Chemical Compounds: Minerals like potassium chloride and zinc sulphate are refined for agricultural and chemical uses.

4. Manufacturing Finished Products

The refined minerals are then used to manufacture finished products that cater to various industries.

- Construction: Silica sand is used in glassmaking, and cement clinker becomes concrete for infrastructure.

- Energy Storage: Nickel and cobalt powders are integral to the production of lithium-ion batteries.

- Consumer Goods: Carbon blocks and graphite are used in high-tech electronics and lubricants.

- Agriculture: Compost fertilizers and potassium chloride are vital for enhancing crop productivity.

5. Quality Control and Assurance

Throughout the journey, stringent quality control measures are implemented to ensure the materials meet industry standards. Advanced testing labs and certification processes play a crucial role in guaranteeing consistency, performance, and safety.

- Testing Parameters: Purity, particle size, chemical composition, and durability are evaluated.

- Automation in Quality Control: AI and IoT-powered sensors now help monitor and optimize the quality of materials in real-time.

6. Packaging and Distribution

Once transformed into finished products, industrial minerals are packaged and distributed to meet global demands. Customizable packaging options ensure safe transport and easy handling for clients.

- Sustainability in Packaging: Increasing use of recyclable and biodegradable materials for packaging industrial minerals.

- Efficient Logistics: Sophisticated supply chain management systems ensure timely delivery to industries worldwide.

7. Applications Across Industries

The journey comes full circle as these minerals power industries ranging from construction and manufacturing to technology and agriculture. Their applications include:

- Infrastructure Development: Cement clinker and silica sand are foundational to modern construction.

- Technology Advancements: Metal powders and graphite drive innovation in batteries and electronics.

- Sustainable Farming: Compost fertilizers and potassium chloride support eco-friendly agriculture.

Innovations Shaping the Future

The industrial minerals industry continues to evolve with breakthroughs in technology and sustainability practices. Emerging trends include:

- Recycling and Circular Economy: Reclaiming and reusing industrial minerals to reduce waste.

- Nanotechnology: Enhancing the performance of materials like carbon and graphite for advanced applications.

- Green Mining: Using renewable energy and environmentally friendly techniques to minimize mining impact.

Kartikey Biotech: Partnering in Progress

With over 14 years of experience, Kartikey Biotech is at the forefront of supplying premium-quality industrial minerals, chemicals, and raw materials. Our journey is rooted in a commitment to sustainability, innovation, and delivering unparalleled quality.

We provide tailored solutions across industries, ensuring our clients receive materials that drive efficiency and productivity in their operations.

Conclusion

The journey of industrial minerals is a testament to human ingenuity and the power of innovation. From raw materials to finished products, every stage of this process is vital in shaping the modern world. As industries demand more sustainable and efficient solutions, the role of industrial minerals will continue to expand, fueling progress and driving global development.

Explore the transformative journey of industrial minerals with Kartikey Biotech. Contact us today for premium-quality materials tailored to your needs. Together, we’ll build a better tomorrow.