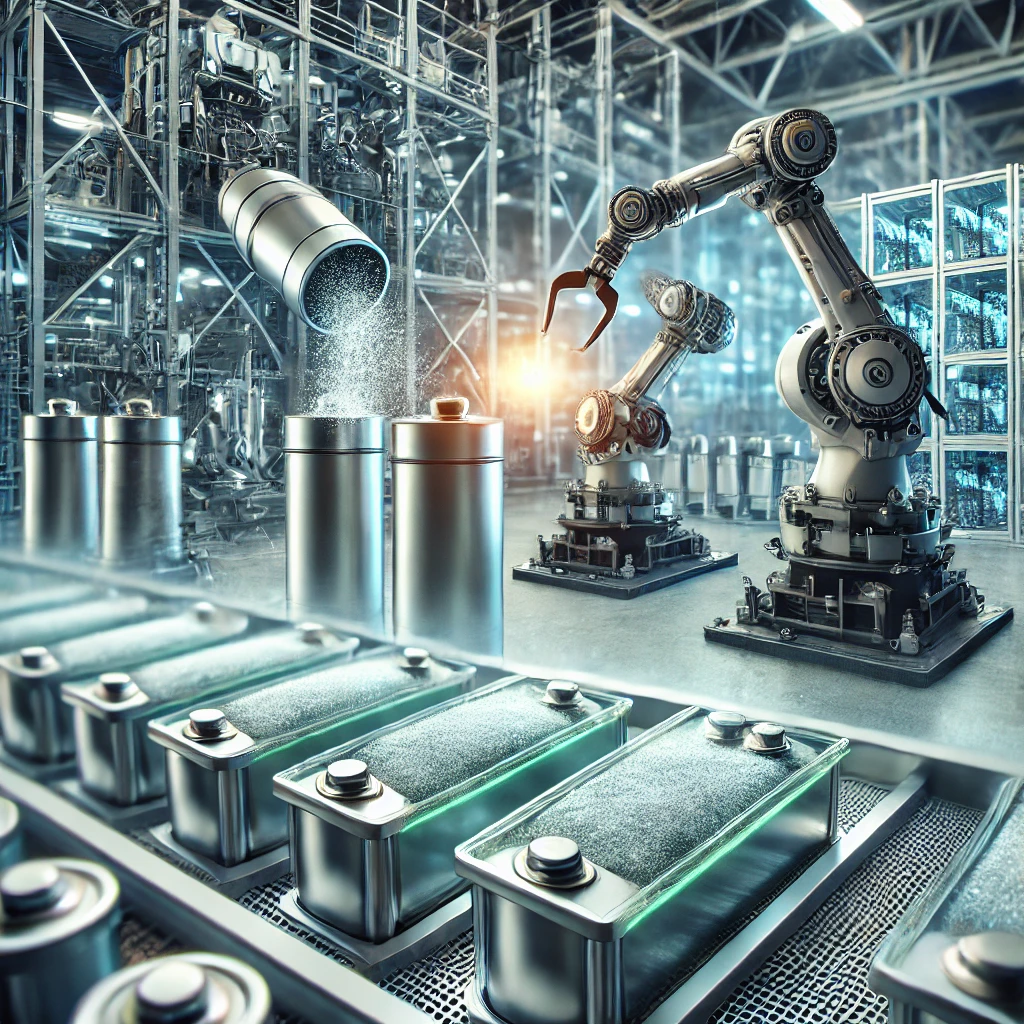

Benefits of High-Quality Metal Powders in Battery Manufacturing

The rapid growth of renewable energy and electric vehicles (EVs) has made battery manufacturing a cornerstone of modern technology. At the heart of this innovation are high-quality metal powders, which play a critical role in improving the efficiency, performance, and longevity of batteries. These powders, including nickel, cobalt, and aluminum, are indispensable for producing batteries that meet the demands of advanced industries.

In this blog, we explore how high-quality metal powders are revolutionizing battery manufacturing and why they are essential for shaping the future of energy storage.

1. Enhancing Energy Density

High-quality metal powders contribute to higher energy density in batteries, allowing them to store more energy in a compact size. For instance, nickel and cobalt powders used in cathodes of lithium-ion batteries enable superior energy storage capabilities. This advancement is critical for industries like electric vehicles, where compact batteries with extended ranges are highly valued.

2. Improving Conductivity and Efficiency

Metal powders like copper and aluminum are integral to improving the electrical conductivity of batteries. These materials ensure efficient current flow within the battery, minimizing energy loss and maximizing performance. With high-quality powders, manufacturers can produce batteries that charge faster and operate more efficiently, making them ideal for applications in renewable energy and consumer electronics.

3. Extending Battery Lifespan

The purity and consistency of metal powders significantly impact the durability of batteries. Impurities in lower-grade powders can cause degradation over time, leading to shorter battery life. High-quality powders, on the other hand, ensure uniformity and stability, reducing wear and tear and extending the lifespan of the battery. This benefit is crucial for industries like electric vehicles and grid energy storage, where reliability is non-negotiable.

4. Enabling Compact and Lightweight Designs

Advancements in metal powder technology enable the production of thinner and more lightweight battery components without compromising performance. Aluminum and magnesium powders are often used to achieve this balance, making batteries more portable and easier to integrate into compact devices like smartphones, laptops, and drones.

5. Supporting Sustainability Efforts

Sustainable energy solutions are at the forefront of modern innovation, and high-quality metal powders play a pivotal role. Their efficient performance reduces energy waste during battery operation, and their recyclability supports circular economy initiatives. Many manufacturers now focus on using recycled metal powders to further minimize environmental impact.

6. Facilitating Next-Generation Battery Technologies

Emerging technologies such as solid-state batteries and sodium-ion batteries rely heavily on the quality of metal powders. These next-generation batteries promise improved safety, performance, and cost-effectiveness. High-quality powders ensure the precision and stability needed to bring these innovative solutions to market.

7. Reducing Manufacturing Defects

In battery production, consistency is key. Variations in metal powder quality can lead to defects, causing inefficiencies and even safety risks such as overheating or short circuits. High-quality powders reduce these risks by providing consistent particle size, shape, and purity, resulting in batteries that are safer and more reliable.

8. Applications Across Industries

The benefits of high-quality metal powders extend beyond automotive and energy storage. They are also crucial in manufacturing batteries for aerospace, medical devices, and industrial machinery. As these industries demand higher performance and reliability, the need for premium-grade powders becomes even more pronounced.

Why Quality Matters in Metal Powders

Investing in high-quality metal powders is not just about achieving better battery performance; it’s about meeting the growing expectations of industries and consumers. Quality impacts every aspect of battery manufacturing, from production efficiency and cost-effectiveness to safety and sustainability.

Kartikey Biotech: Your Trusted Partner for High-Quality Metal Powders

At Kartikey Biotech, we understand the importance of quality in battery manufacturing. With over 14 years of expertise, we provide premium-grade metal powders like nickel, cobalt, aluminum, and more, tailored to the specific needs of manufacturers. Our powders are processed under stringent quality standards, ensuring the purity, consistency, and performance that modern industries demand.

By partnering with Kartikey Biotech, you gain access to reliable materials that enhance the efficiency and sustainability of your battery production processes.

Conclusion

High-quality metal powders are the building blocks of modern battery technology. From enhancing energy density and efficiency to enabling compact designs and supporting sustainability, their benefits are vast and transformative. As the demand for energy storage solutions continues to grow, the role of premium metal powders will only become more critical.

Explore how high-quality metal powders can elevate your battery manufacturing process. Contact Kartikey Biotech today for top-grade materials tailored to your needs. Together, let’s power the future of energy storage.