The Future of Metal Powders: Innovations and Applications

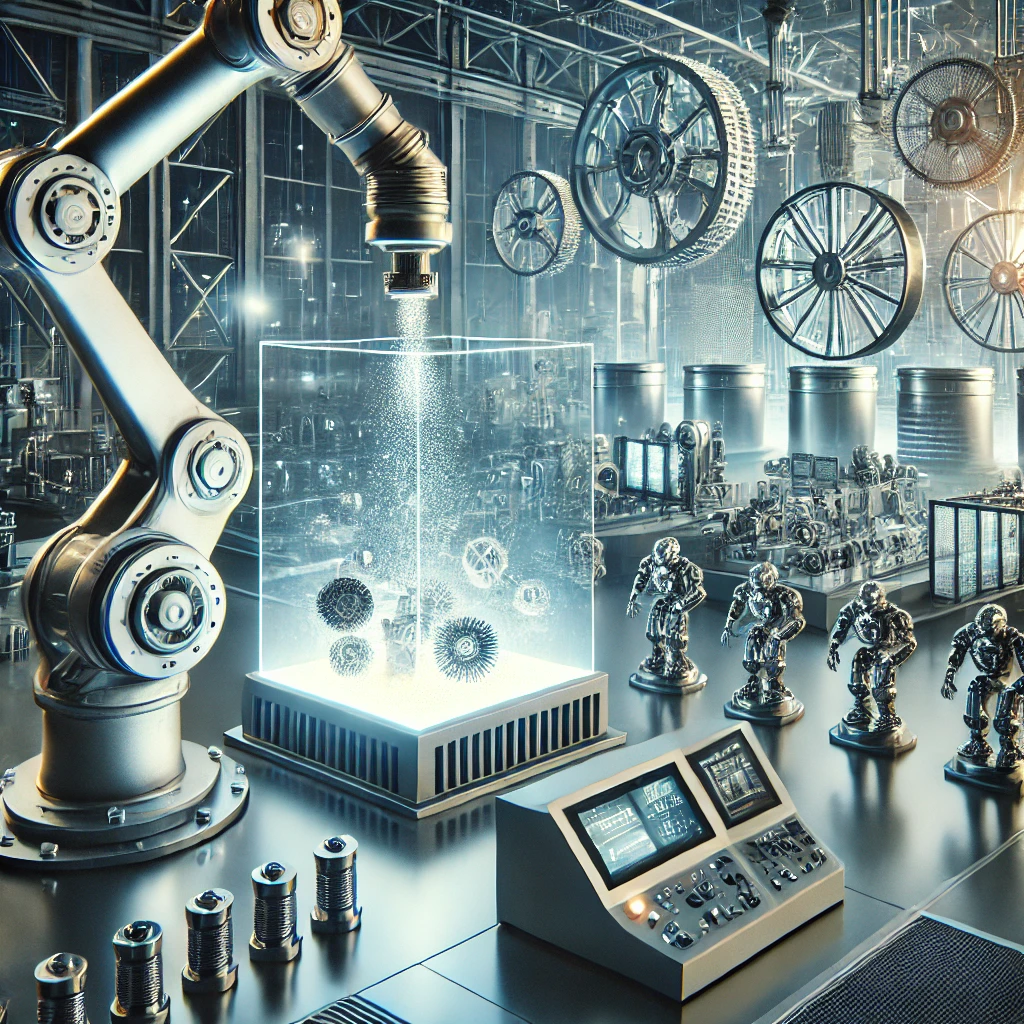

Metal powders have long been a cornerstone of industrial processes, but recent advancements and emerging technologies are unlocking their potential in entirely new ways. From traditional metallurgy to cutting-edge additive manufacturing and sustainable energy solutions, metal powders are reshaping industries and paving the way for groundbreaking innovations.

In this comprehensive blog, we take an in-depth look at the future of metal powders, exploring their role in driving technological progress and addressing the needs of modern industries.

1. Technological Innovations

The production of metal powders has evolved significantly with advancements such as gas and water atomization, plasma rotating electrodes, and mechanical alloying. These methods have improved the purity, consistency, and particle size distribution of metal powders, enabling their use in high-precision applications. Innovations in nanotechnology are further enhancing the properties of metal powders, making them more efficient and versatile than ever before.

2. Additive Manufacturing Revolution

Additive manufacturing, or 3D printing, is one of the most exciting areas where metal powders are making a significant impact. Metal powders enable the creation of complex, custom designs with minimal waste, reducing production costs while maintaining superior performance. Industries such as aerospace, healthcare, and automotive are increasingly relying on 3D printing with metal powders to produce lightweight yet durable components.

3. Sustainable Energy Applications

Metal powders are playing a crucial role in the shift towards renewable energy solutions. They are used in energy storage systems like lithium-ion batteries and hydrogen fuel cells, offering higher energy density and improved efficiency. Metal powders also hold potential for energy generation through thermite reactions and sustainable processes, contributing to the global push for cleaner energy.

4. Aerospace and Automotive Advancements

The aerospace and automotive sectors demand materials that are both lightweight and robust. Metal powders, such as titanium, aluminum, and nickel-based alloys, are ideal for these requirements. They enable the production of high-performance components with excellent thermal and mechanical properties, boosting efficiency and safety in these industries.

5. Focus on Sustainability

As industries become more environmentally conscious, the sustainability of metal powders is gaining attention. Efforts to recycle and reuse metal powders are reducing waste and minimizing the environmental impact of production processes. This trend not only addresses ecological concerns but also lowers costs, making metal powders an even more attractive option for manufacturers.

Challenges and Opportunities

While the future of metal powders is bright, challenges such as scalability, cost-efficiency, and material compatibility must be addressed. Researchers and manufacturers are working to overcome these hurdles through collaborative efforts and investments in technology.

Kartikey Biotech’s Role in the Future of Metal Powders

At Kartikey Biotech, we are committed to supporting the evolution of metal powders by delivering high-quality materials that meet the demands of modern industries. With over 14 years of expertise, we provide reliable and sustainable solutions tailored to a wide range of applications, from traditional metallurgy to advanced energy systems.

The future of metal powders is brimming with possibilities. As innovations continue to emerge, their applications will expand further, revolutionizing industries and driving sustainable growth. Whether you are in manufacturing, energy, or research, staying informed about the advancements in metal powders will empower you to remain competitive in an ever-changing market.

Explore the transformative potential of metal powders with us and stay ahead in the industry’s next big leap forward.